110VAC

Mini diaphragm water pump 5.0L/min 100psi Hot Water Pump 5.0LPM/1.3GPM 100PSI Application: -Agriculture/Yacht / RV/Carav

Description

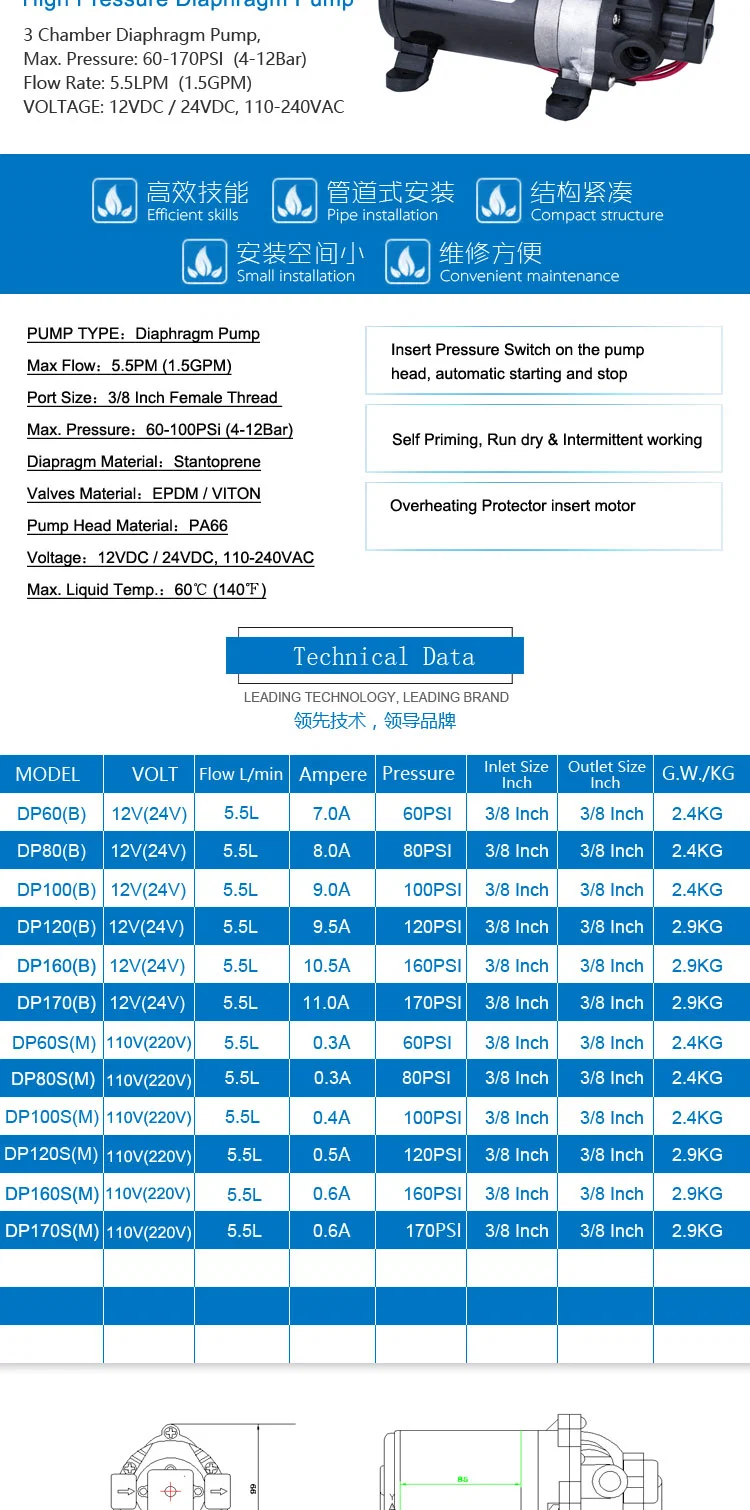

Basic Info.

| Model NO. | DP |

| Structure | Diaphragm Pump |

| Assembly | Liquid Pumps |

| Power | Electric |

| Start Up | Electric Pump |

| Type | Jet Pump |

| Application | Slurry Pump, Chemical Pump |

| Industry | Food Pumps |

| Media | Powder Pump |

| Performance | Automatic Pump |

| Theory | Rotary Pump |

| Duty Cycle | Intermittent |

| Flow Rate | 5.0lpm/1.3gpm |

| Valve | Vtion or EPDM |

| Protection | Thermal/Ignition Protection |

| Diaphragm | Santoprene |

| Port Dimension | 3/8" NPT |

| Pressure | High Pressure,100psi/6.9bar |

| Fuel | 12V DC Power |

| Transport Package | Cartons |

| Specification | CE |

| Trademark | LifeSRC |

| Origin | China |

| HS Code | 8413 |

| Production Capacity | 50000PCS/Month |

Product Description

Mini diaphragm water pump 5.0L/min 100psi Hot Water Pump5.0LPM/1.3GPM 100PSI

Application:

-Agriculture/Yacht / RV/Caravan pressurized water system

-Sprayer fixture (Vehicle-mounted sprayer, electric sprayer)

-Cleaning machine, Humidifier, Water purification, Medical apparatus

-Food beverage filling & liquid transfer

-Any other pressurization system

Materials of Construction

| Motor Housing: | Nylon 6/6 |

| Pump Housing: | Polypropylene |

| Valves: | Vtion |

| Diaphragm: | Santoprene |

| Fasteners: | Stainless steel and Zinc Plated |

| Motor Shell: | Coated Steel |

Pump

| Motor Voltage | 12V/24V |

| Type | 2 chamber positive displacement diaphragm pump, self priming, capable of being run dry |

| Mode | Demand |

| Certifications Option | CE Approval |

| Liquid Temperature | 140°F (60°C) Max. |

| Priming Capabilities | 6 feet (1.8 m) suction lift |

| Max Pressure | 100psi (6.9bar) |

| Max Flow rate | 5.0lpm (1.3gpm) |

| Inlet/Outlet Ports | 3?8" hose barb |

| Duty Cycle | Intermittent |

| Leads | 18 AWG, 9.84" long with 2-pin connector/Lead |

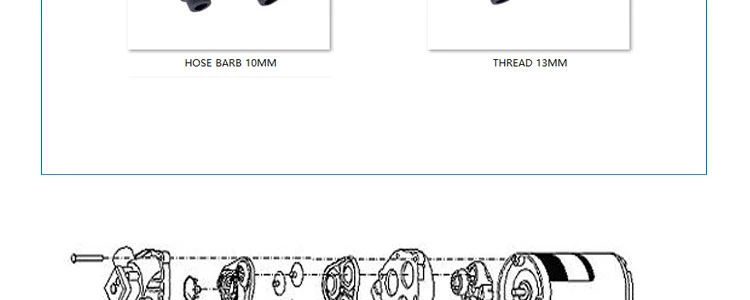

How a Diaphragm Pump Works

The pump is driven by an AC or DC motor

In front of the motor is a valve assembly containing two to five valve pump chambers. Each valve chamber has a diaphragm behind it in the lower pump housing. As the motor shaft turns, an internal cam positioned behind the diaphragms causes the diaphragms to be pushed forward, then back in a continuous sequence creating a suction. As this suction builds, fluid is pulled through the inlet, through the various valve chamber check valves to the outlet

The volume of flow is determined by several factors including: the number and size of the pump chambers, cam offset, operating pressure, fluid viscosity

Our Contact

Send now